- Products

- Commercial divers’ equipment

- Compasses and watches

- Defence divers’ equipment

- Diving instrumentation

- Electrical diving equipment

- Escape and abandonment

- Gas and fluid systems

- Medical and safety equipment

- Recompression chambers

- Submarine intervention

- Submarine rescue

- Tactical Diving Vehicles

- Ansti testing equipment

- Services

- Consultancy and personnel

- Engineering services

- Rescue and support

- Testing services

- Training services

- Ancillary dive gear

- Commercial equipment and tools

- Commercial helmets, masks and SCUBA

- Commercial rebreathers

- Commercial surface supply

- Diver's suits and harnesses

- Contaminated water diving system

- BIBS manifold block

- Divex back pressure regulator

- Divex interlock

- Hy-Fex hyperbaric fire extinguisher

- Hyperbaric flame detector

- Hyperlite hyperbaric stretcher

- Oxygen kits

- Ultralite 2 BIBS mask

- InVicto ventilator system

- DSAR rescue vehicles

- Launch and recovery systems

- Multi-role launch and recovery system

- Submarine rescue bell

- Client representatives

- Dive and ROV system audits

- Diving technical expertise

- Offshore personnel

- Rescue certification

- Remote audit solution

- Altitude testing and trials

- Hyperbaric welding

- Pressure testing and trials

- Test tank

- Breathing laboratory

- Commercial development courses

- Defence training courses

- Medical training courses

- Product specific courses

- Online training courses

- Classroom training FAQ

- Case Study: Roger Chapman Pisces III

- Case Study: HMS Edinburgh

- ANSTI CSTF

- Akademik Tofiq Ismayilov (ATI)

- Archive

- JFD strengthens Commercial Diving business with leadership appointments

- JFD unveils new product concept ‘Stealth Multi-Role’ at key industry events

- JFD North America enhances US Navy Submarine Rescue capabilities with advanced Integrated Communication System

- JFD successfully integrates and delivers advanced submarine rescue system for Republic of Korea Navy

- Archive

- Divulged - Winter 2017

- Divulged - Summer 2017

- Divulged - Winter 2016

- Divulged - Summer 2018

- Divulged - Winter 2018

- Divulged - Winter 2019

- Divulged 2021 Edition 1

- UDT 2019

- Visit JFD at UI 2016

- Visit us at OTC Asia 2018

- Visit JFD on stand 338 at Underwater Intervention 2018

- JFD is exhibiting at ONS 2018

- JFD is exhibiting at OSEA 2018

- Join JFD at IDEX 2019

- See JFD at Subsea Expo 2019

- JFD takes on BALT Military Expo

- JFD presents complete defence offering at UDT 2018 in Glasgow

- Join JFD at ADIPEC 2018

- Visit JFD at Pacific 2017

- Visit JFD at MSPO 2018 in Poland

- JFD presenting at UDT conference

- JFD is exhibiting alongside James Fisher Nigeria at NOG

- JFD exhibiting at UDT 2016

- Visit JFD at Underwater Intervention 2019

- JFD is participating at Underwater Defence & Security

- See JFD at this year’s IMCA Annual Seminar

- JFD is exhibiting at LAAD Defence & Security 2019

- JFD LEXMAR is exhibiting at OSEA 2016

- JFD is exhibiting at Subsea Expo 2017

- Visit JFD at Indo Defence 2018 Expo and Forum

- Visit JFD on stand 403 at Underwater Intervention 2017

- JFD exhibiting at Europoltech

- JFD at IMDEX

- Visit JFD at UDT 2017

- Visit JFD at DSEI 2017

- JFD is exhibiting at OTC 2018

- JFD is exhibiting at Subsea EXPO 2018

- JFD is exhibiting at Sea Air Space 2018

- Visit JFD at DSA 2018

- See JFD at Defexpo 2018

- JFD is exhibiting at ADIPEC 2017

- Come see JFD at DSEI!

- See JFD at IMDEX Asia 2019

- JFD is at Oil & Gas Asia 2019

- Experience DSEI with JFD

- See JFD's full defence capability at MSPO 2019

- JFD is exhibiting at this year's Offshore Europe

- Visit us on stand 2S16 at Pacific

- See JFD at ADIPEC on stand 13572

- Explore our commercial capabilities at Bergen International Diving Seminar

- JFD showcasing commercial and defence capabilities at Underwater Intervention

- JFD exhibiting alongside James Fisher Offshore at Subsea Expo

- Visit our stand at DSEI 2021!

- Join JFD at Subsea Expo 2022

- Visit JFD Australia at Indo Pacific 2022

- JFD North America is exhibiting at SOFIC 2022

- Experience CNE 2022 with JFD

- Discover JFD at UDT 2022

- Join JFD at GSOF Symposium Europe this October

Case study: JFO dive tank testing

Release date: 18 December 2020

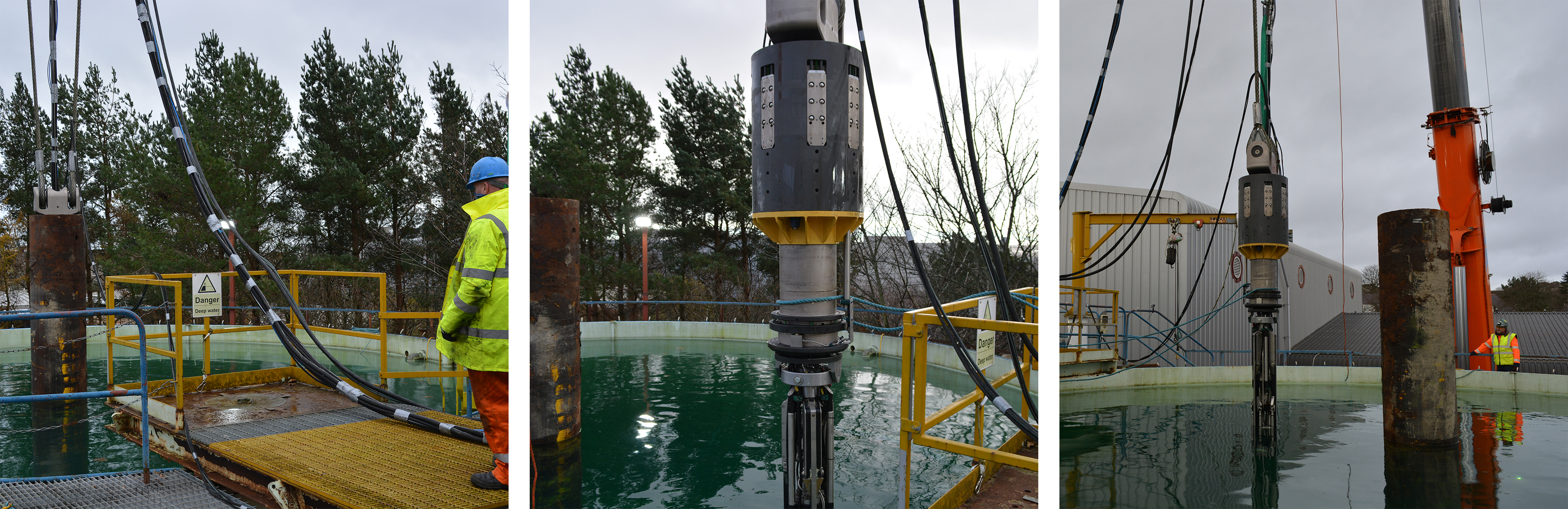

James Fisher Offshore ICLT test

| Client | Completed | Service |

| James Fisher Offshore | November 2020 | Testing |

THE REQUIREMENT

James Fisher Offshore (JFO) needed to be able to test and demonstrate their innovative cutting tool, Internal Cut and Lift Technology (ICLT), in a controlled and safe water environment.

THE SOLUTION

JFD was able to host the test and demonstration at its National Hyperbaric centre, using the 900,000 litre steel dive tank, yard and office facilities.

In advance of the test and demonstration, JFD technicians drained the test tank and installed underwater cameras inside enabling JFO to film their tool cutting pipe underwater.

JFD set up the boardroom onsite, which overlooks the dive tank, for JFO and clients to use during the trial. This included a live feed of images from the underwater cameras displayed to the screen in the boardroom so they could view the demonstration in real time.

A crane was hired to support the lifting of the tool and equipment in and out of the tank during both the dummy run and live demonstration.

JFO used the yard beside the tank not only for their equipment, which was supporting the test, but also as a lay down area for the cut pipe to demonstrate the effectiveness of the tool to the client.

OUTCOME

The test and demonstration was very successful and it enabled JFO to exhibit the effectiveness of their cutting and lifting tool in one location both safely and efficiently.

JFO’s clients were able to witness in real time how the tool worked and also see up close the end results of the cutting technology.

ICLT Dive Tank Test - Case Study

Published 16 July 2021

Scott Paterson, Commercial Services Sales, gives a presentation on the ICLT dive tank test case study.