- Products

- Commercial divers’ equipment

- Compasses and watches

- Defence divers’ equipment

- Diving instrumentation

- Electrical diving equipment

- Escape and abandonment

- Gas and fluid systems

- Medical and safety equipment

- Recompression chambers

- Submarine intervention

- Submarine rescue

- Tactical Diving Vehicles

- Ansti testing equipment

- Services

- Consultancy and personnel

- Engineering services

- Rescue and support

- Testing services

- Training services

- Ancillary dive gear

- Commercial equipment and tools

- Commercial helmets, masks and SCUBA

- Commercial rebreathers

- Commercial surface supply

- Diver's suits and harnesses

- Contaminated water diving system

- BIBS manifold block

- Divex back pressure regulator

- Divex interlock

- Hy-Fex hyperbaric fire extinguisher

- Hyperbaric flame detector

- Hyperlite hyperbaric stretcher

- Oxygen kits

- Ultralite 2 BIBS mask

- InVicto ventilator system

- DSAR rescue vehicles

- Launch and recovery systems

- Multi-role launch and recovery system

- Submarine rescue bell

- Client representatives

- Dive and ROV system audits

- Diving technical expertise

- Offshore personnel

- Rescue certification

- Remote audit solution

- Altitude testing and trials

- Hyperbaric welding

- Pressure testing and trials

- Test tank

- Breathing laboratory

- Commercial development courses

- Defence training courses

- Medical training courses

- Product specific courses

- Online training courses

- Classroom training FAQ

- Case Study: Roger Chapman Pisces III

- Case Study: HMS Edinburgh

- ANSTI CSTF

- Akademik Tofiq Ismayilov (ATI)

- Archive

- JFD strengthens Commercial Diving business with leadership appointments

- JFD unveils new product concept ‘Stealth Multi-Role’ at key industry events

- JFD North America enhances US Navy Submarine Rescue capabilities with advanced Integrated Communication System

- JFD successfully integrates and delivers advanced submarine rescue system for Republic of Korea Navy

- Archive

- Divulged - Winter 2017

- Divulged - Summer 2017

- Divulged - Winter 2016

- Divulged - Summer 2018

- Divulged - Winter 2018

- Divulged - Winter 2019

- Divulged 2021 Edition 1

- UDT 2019

- Visit JFD at UI 2016

- Visit us at OTC Asia 2018

- Visit JFD on stand 338 at Underwater Intervention 2018

- JFD is exhibiting at ONS 2018

- JFD is exhibiting at OSEA 2018

- Join JFD at IDEX 2019

- See JFD at Subsea Expo 2019

- JFD takes on BALT Military Expo

- JFD presents complete defence offering at UDT 2018 in Glasgow

- Join JFD at ADIPEC 2018

- Visit JFD at Pacific 2017

- Visit JFD at MSPO 2018 in Poland

- JFD presenting at UDT conference

- JFD is exhibiting alongside James Fisher Nigeria at NOG

- JFD exhibiting at UDT 2016

- Visit JFD at Underwater Intervention 2019

- JFD is participating at Underwater Defence & Security

- See JFD at this year’s IMCA Annual Seminar

- JFD is exhibiting at LAAD Defence & Security 2019

- JFD LEXMAR is exhibiting at OSEA 2016

- JFD is exhibiting at Subsea Expo 2017

- Visit JFD at Indo Defence 2018 Expo and Forum

- Visit JFD on stand 403 at Underwater Intervention 2017

- JFD exhibiting at Europoltech

- JFD at IMDEX

- Visit JFD at UDT 2017

- Visit JFD at DSEI 2017

- JFD is exhibiting at OTC 2018

- JFD is exhibiting at Subsea EXPO 2018

- JFD is exhibiting at Sea Air Space 2018

- Visit JFD at DSA 2018

- See JFD at Defexpo 2018

- JFD is exhibiting at ADIPEC 2017

- Come see JFD at DSEI!

- See JFD at IMDEX Asia 2019

- JFD is at Oil & Gas Asia 2019

- Experience DSEI with JFD

- See JFD's full defence capability at MSPO 2019

- JFD is exhibiting at this year's Offshore Europe

- Visit us on stand 2S16 at Pacific

- See JFD at ADIPEC on stand 13572

- Explore our commercial capabilities at Bergen International Diving Seminar

- JFD showcasing commercial and defence capabilities at Underwater Intervention

- JFD exhibiting alongside James Fisher Offshore at Subsea Expo

- Visit our stand at DSEI 2021!

- Join JFD at Subsea Expo 2022

- Visit JFD Australia at Indo Pacific 2022

- JFD North America is exhibiting at SOFIC 2022

- Experience CNE 2022 with JFD

- Discover JFD at UDT 2022

- Join JFD at GSOF Symposium Europe this October

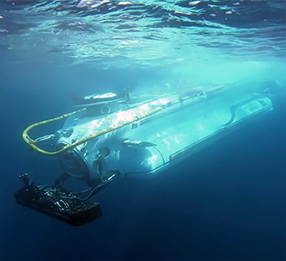

DSAR rescue vehicles

Reliable, flexible and proven free-swimming DSAR Class SRV.

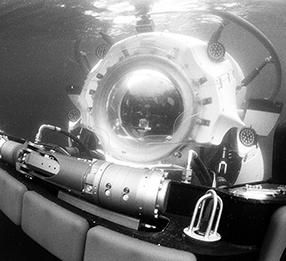

The design of JFD's deep search and rescue (DSAR) submarine rescue vehicle is built upon more than 25 years of submarine rescue operational experience.

Operating up to 500msw the submarine rescue vehicle has capacity for a crew of 3 plus up to 16 rescuees. With an integrated dry mating skirt, Lithium Polymer battery system and 108 hours of life support the DSAR-500L is capable of mating at angles of up to 60 degrees and operating in currents of up to 3 knots.and

operating in currents of up to 3 knots.

|

|

||||||

|

|

|

|

|

The system is adaptable and reliant on ‘simple’ technology which can be repaired and maintained offshore with a manageable spares and tools package.

The weight of the SRV has been minimised, a reduction in its standalone weight allows benefits across the whole of the submarine rescue system; a lighter total system weight maximises the range of VOOs (vessel of opportunities) to which the system can be mobilised.

The below specification is based on our DSAR-500L Class vehicle. Other depths are available on request. JFD have delivered vehicles certified for depths up to 650msw.

Rescue capability

|

Operating depth |

500msw* |

|

Maximum speed |

> 3 knots |

|

Operational endurance |

Up to 12 hours |

|

Emergency life support |

> 108 hours |

|

Maximum mating angle |

60 degrees |

| Rescue payload | 1,200 kg |

|

Air transportability |

AN124, C17 or similar |

*other depths available on request. JFD have delivered vehicles certified for depths up to 650msw.

Principle particulars

| Length |

10.7m |

|

Beam |

3.2m |

|

Depth |

2.8m |

| In air weight | < 28 tonnes |

|

Main propulsion |

2 x 15kW electric |

|

Auxiliary propulsion |

4 x electric |

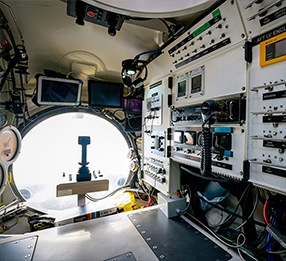

Electrical System

|

Battery system |

Lithium polymer |

|

System voltage |

120V / 24V with 24V emergency supply |

|

Navigation |

Integrated navigation suite |

| Automation |

Autopilot, auto depth, altitude and heading hold |

|

Communications |

Through-water audio and data |

|

Logging |

Video, communications and data logging for review and training |

Design standards

|

Classification |

Classed to Lloyd's Register Rules and regulations for classification of submersibles |

|

Pressure vessel code |

PD5500:2018 specification for Unfired Fusion Welded Pressure Vessels |

|

Mating skirt |

STANAG 1475 and ANEP/MNEP 85 |

DSAR-5 (ROKS-DSRV-II)

In 2009 JFD delivered into service ROKS-DSRV-II (formerly "DSAR-5") to the Republic of Korea Navy. ROKS-DSRV-II was formally accepted into service on time and to budget on December 22nd in a service onboard the dedicated mothership, Cheong Hae Jin.

DSAR-6

In 2010 JFD delivered DSAR-6 to the Republic of Singapore. DSAR-6 is operated from a dedicated rescue mothership, "Swift Rescue". Under a twenty-year contract to the Republic of Singapore Navy, JFD and partner ST Marine are responsible for the provision of a complete submarine rescue service.

DSAR-500L / DSAR-650L

JFD currently have 2 DSAR-500 Class DRSVs and 2 DSAR-650L (rated to 650m) in full operational service. By the end of 2021 a number of additional DSAR-500L vehicles fully classed by Lloyds’ Register will be delivered to new and existing customers.

Fabrication & Machining

JFD have worked with cutting edge materials in order to offer extreme operational endurance and improved crew and rescue ergonomics volumes whilst remaining within the weight limits of previous generation vehicles.

Working in partnership with proven suppliers worldwide, our research & development team has ensured that the materials and approaches used within the DSAR-500L are of optimum quality and performance.

Precision manufacturing underpins our commitment to excellence.

Build Strategy

An innovative modular strategy shortens the build timescale and reduces risk. Continuous unrestricted access is achieved, allowing early testing and build completion in under 24 months.

DSAR is designed, built and maintained in accordance with exacting international standards.

All systems are assembled, commissioned and tested under the watchful eye of Lloyd's Register.

The system is adaptable and reliant on ‘simple’ technology which can be repaired and maintained offshore with a manageable spares and tools package.

The weight of the SRV has been minimised, a reduction in its standalone weight allows benefits across the whole of the submarine rescue system; a lighter total system weight maximises the range of VOOs (vessel of opportunities) to which the system can be mobilised.

The below specification is based on our DSAR-500L Class vehicle. Other depths are available on request. JFD have delivered vehicles certified for depths up to 650msw.

Rescue capability

|

Operating depth |

500msw* |

|

Maximum speed |

> 3 knots |

|

Operational endurance |

Up to 12 hours |

|

Emergency life support |

> 108 hours |

|

Maximum mating angle |

60 degrees |

| Rescue payload | 1,200 kg |

|

Air transportability |

AN124, C17 or similar |

*other depths available on request. JFD have delivered vehicles certified for depths up to 650msw.

Principle particulars

| Length |

10.7m |

|

Beam |

3.2m |

|

Depth |

2.8m |

| In air weight | < 28 tonnes |

|

Main propulsion |

2 x 15kW electric |

|

Auxiliary propulsion |

4 x electric |

Electrical System

|

Battery system |

Lithium polymer |

|

System voltage |

120V / 24V with 24V emergency supply |

|

Navigation |

Integrated navigation suite |

| Automation |

Autopilot, auto depth, altitude and heading hold |

|

Communications |

Through-water audio and data |

|

Logging |

Video, communications and data logging for review and training |

Design standards

|

Classification |

Classed to Lloyd's Register Rules and regulations for classification of submersibles |

|

Pressure vessel code |

PD5500:2018 specification for Unfired Fusion Welded Pressure Vessels |

|

Mating skirt |

STANAG 1475 and ANEP/MNEP 85 |

DSAR-5 (ROKS-DSRV-II)

In 2009 JFD delivered into service ROKS-DSRV-II (formerly "DSAR-5") to the Republic of Korea Navy. ROKS-DSRV-II was formally accepted into service on time and to budget on December 22nd in a service onboard the dedicated mothership, Cheong Hae Jin.

DSAR-6

In 2010 JFD delivered DSAR-6 to the Republic of Singapore. DSAR-6 is operated from a dedicated rescue mothership, "Swift Rescue". Under a twenty-year contract to the Republic of Singapore Navy, JFD and partner ST Marine are responsible for the provision of a complete submarine rescue service.

DSAR-500L / DSAR-650L

JFD currently have 2 DSAR-500 Class DRSVs and 2 DSAR-650L (rated to 650m) in full operational service. By the end of 2021 a number of additional DSAR-500L vehicles fully classed by Lloyds’ Register will be delivered to new and existing customers.

Fabrication & Machining

JFD have worked with cutting edge materials in order to offer extreme operational endurance and improved crew and rescue ergonomics volumes whilst remaining within the weight limits of previous generation vehicles.

Working in partnership with proven suppliers worldwide, our research & development team has ensured that the materials and approaches used within the DSAR-500L are of optimum quality and performance.

Precision manufacturing underpins our commitment to excellence.

Build Strategy

An innovative modular strategy shortens the build timescale and reduces risk. Continuous unrestricted access is achieved, allowing early testing and build completion in under 24 months.

DSAR is designed, built and maintained in accordance with exacting international standards.

All systems are assembled, commissioned and tested under the watchful eye of Lloyd's Register.