- Products

- Commercial divers’ equipment

- Compasses and watches

- Defence divers’ equipment

- Diving instrumentation

- Electrical diving equipment

- Escape and abandonment

- Gas and fluid systems

- Medical and safety equipment

- Recompression chambers

- Submarine intervention

- Submarine rescue

- Tactical Diving Vehicles

- Ansti testing equipment

- Services

- Consultancy and personnel

- Engineering services

- Rescue and support

- Testing services

- Training services

- Ancillary dive gear

- Commercial equipment and tools

- Commercial helmets, masks and SCUBA

- Commercial rebreathers

- Commercial surface supply

- Diver's suits and harnesses

- Contaminated water diving system

- BIBS manifold block

- Divex back pressure regulator

- Divex interlock

- Hy-Fex hyperbaric fire extinguisher

- Hyperbaric flame detector

- Hyperlite hyperbaric stretcher

- Oxygen kits

- Ultralite 2 BIBS mask

- InVicto ventilator system

- DSAR rescue vehicles

- Launch and recovery systems

- Multi-role launch and recovery system

- Submarine rescue bell

- Client representatives

- Dive and ROV system audits

- Diving technical expertise

- Offshore personnel

- Rescue certification

- Remote audit solution

- Altitude testing and trials

- Hyperbaric welding

- Pressure testing and trials

- Test tank

- Breathing laboratory

- Commercial development courses

- Defence training courses

- Medical training courses

- Product specific courses

- Online training courses

- Classroom training FAQ

- Case Study: Roger Chapman Pisces III

- Case Study: HMS Edinburgh

- ANSTI CSTF

- Akademik Tofiq Ismayilov (ATI)

- Archive

- JFD strengthens Commercial Diving business with leadership appointments

- JFD unveils new product concept ‘Stealth Multi-Role’ at key industry events

- JFD North America enhances US Navy Submarine Rescue capabilities with advanced Integrated Communication System

- JFD successfully integrates and delivers advanced submarine rescue system for Republic of Korea Navy

- Archive

- Divulged - Winter 2017

- Divulged - Summer 2017

- Divulged - Winter 2016

- Divulged - Summer 2018

- Divulged - Winter 2018

- Divulged - Winter 2019

- Divulged 2021 Edition 1

- UDT 2019

- Visit JFD at UI 2016

- Visit us at OTC Asia 2018

- Visit JFD on stand 338 at Underwater Intervention 2018

- JFD is exhibiting at ONS 2018

- JFD is exhibiting at OSEA 2018

- Join JFD at IDEX 2019

- See JFD at Subsea Expo 2019

- JFD takes on BALT Military Expo

- JFD presents complete defence offering at UDT 2018 in Glasgow

- Join JFD at ADIPEC 2018

- Visit JFD at Pacific 2017

- Visit JFD at MSPO 2018 in Poland

- JFD presenting at UDT conference

- JFD is exhibiting alongside James Fisher Nigeria at NOG

- JFD exhibiting at UDT 2016

- Visit JFD at Underwater Intervention 2019

- JFD is participating at Underwater Defence & Security

- See JFD at this year’s IMCA Annual Seminar

- JFD is exhibiting at LAAD Defence & Security 2019

- JFD LEXMAR is exhibiting at OSEA 2016

- JFD is exhibiting at Subsea Expo 2017

- Visit JFD at Indo Defence 2018 Expo and Forum

- Visit JFD on stand 403 at Underwater Intervention 2017

- JFD exhibiting at Europoltech

- JFD at IMDEX

- Visit JFD at UDT 2017

- Visit JFD at DSEI 2017

- JFD is exhibiting at OTC 2018

- JFD is exhibiting at Subsea EXPO 2018

- JFD is exhibiting at Sea Air Space 2018

- Visit JFD at DSA 2018

- See JFD at Defexpo 2018

- JFD is exhibiting at ADIPEC 2017

- Come see JFD at DSEI!

- See JFD at IMDEX Asia 2019

- JFD is at Oil & Gas Asia 2019

- Experience DSEI with JFD

- See JFD's full defence capability at MSPO 2019

- JFD is exhibiting at this year's Offshore Europe

- Visit us on stand 2S16 at Pacific

- See JFD at ADIPEC on stand 13572

- Explore our commercial capabilities at Bergen International Diving Seminar

- JFD showcasing commercial and defence capabilities at Underwater Intervention

- JFD exhibiting alongside James Fisher Offshore at Subsea Expo

- Visit our stand at DSEI 2021!

- Join JFD at Subsea Expo 2022

- Visit JFD Australia at Indo Pacific 2022

- JFD North America is exhibiting at SOFIC 2022

- Experience CNE 2022 with JFD

- Discover JFD at UDT 2022

- Join JFD at GSOF Symposium Europe this October

Pressure testing

JFD maintains one of the largest hyperbaric test facilities in the UK and provides an impressive suite of services for research, development and testing.

Our facilities are amongst the largest in the world, capable of simulating depths up to 800bar and altitudes of 55,000ft.

We offer a complete capability, from design and manufacture. Through to operation, maintenance and training.

The variety of chambers enable us to pressure test a wide range of equipment of all shapes and sizes such as subsea control modules, umbilicals, valves, actuators, ROV and submersible vehicles, buoyancy control devices and underwater housings. Alongside the capacity to altitude test equipment and products across a range of markets.

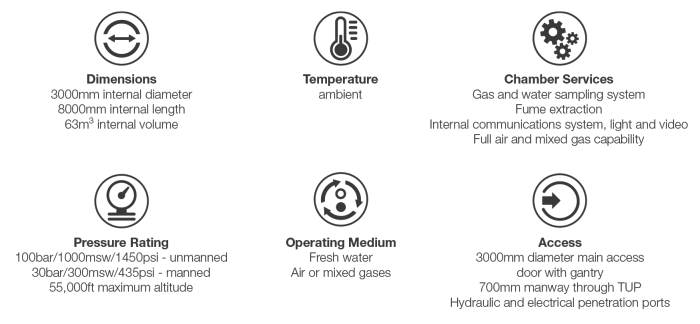

At the heart of the National Hyperbaric Centre is a deep simulation facility capable of manned and unmanned testing. The hydrostatic test chamber can simulate subsea environmental conditions to a depth of 1,000msw and altitudes to a height of 55,000ft at ambient temperatures.

|

|

|

|

|

|

| Work Chamber | Work chamber showing access door | Submarine testing within work chamber | Manned trials | Valve testing within work chamber |

|

|

|

|

|

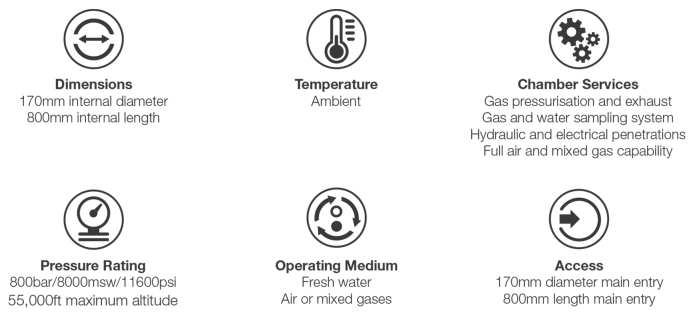

800 bar chamber

The National Hyperbaric Centre’s deep equipment chamber is again similar to its other chambers but has a much higher pressure rating, down to an impressive 8000m and again is ideal for power supplies, cable assemblies, small electrical housings, underwater cameras and lights in a wet, dry or gas filled environment.

|

|

|

|

|

|

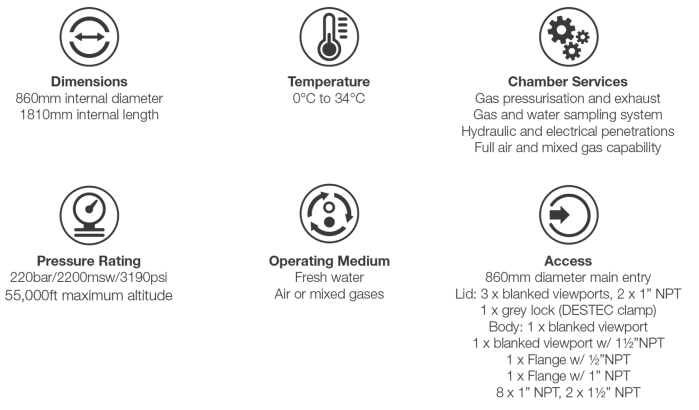

220 bar chamber

National Hyperbaric Centre also has several smaller chambers, including our 220bar chamber, capable of pressure testing to 2200m. With internal access of 860mm wide and 1800mm deep this chamber is ideal for valve, actuator, pump, flow metre and cable assemblies including connections and penetrators.

|

|

|

|

|

|

200 bar chamber

This medium equipment chamber has a working pressure of 200bar and is ideal for pressure testing power supplies, cable assemblies, small electrical housings, underwater cameras and lights. One of the features of this chamber is its 6 multi-way penetration ports which allows easy access for monitoring equipment testing.

|

|

|

|

|

|

Viewport test Jig

A viewport jig for high pressure testing of acrylic viewports used in saturation diving complexes and submarines is available at the NHC.

The use of acrylic plastic viewports has been standard for many years, however the development of polarised light testing has shown that there are various misconceptions about them. Acrylic viewports which are used under pressure are subjected to an increased rate of yield, giving them a slight permanent deformation and inbuilt stress. It is generally agreed that acrylic viewports should be replaced after 10 years of service.

Referring to IMCA guidance D047, viewports should be certified before use:

“Viewports should be subjected to proof stress testing and relevant certification provided

before installation.”

“All viewports in a pressure system need to be rated to the design pressure of the system.”

“Viewports which are not marked or properly documented should not be used.”

All viewport tests are independently witnessed by a class society. Successfully tested viewports are marked with indelible ink - date of examination.

|

|

Facilities |

|

|

|

At the heart of the National Hyperbaric Centre is a deep simulation facility capable of manned and unmanned testing. The hydrostatic test chamber can simulate subsea environmental conditions to a depth of 1,000msw and altitudes to a height of 55,000ft at ambient temperatures.

|

|

|

|

|

|

| Work Chamber | Work chamber showing access door | Submarine testing within work chamber | Manned trials | Valve testing within work chamber |

|

|

|

|

|

800 bar chamber

The National Hyperbaric Centre’s deep equipment chamber is again similar to its other chambers but has a much higher pressure rating, down to an impressive 8000m and again is ideal for power supplies, cable assemblies, small electrical housings, underwater cameras and lights in a wet, dry or gas filled environment.

|

|

|

|

|

|

220 bar chamber

National Hyperbaric Centre also has several smaller chambers, including our 220bar chamber, capable of pressure testing to 2200m. With internal access of 860mm wide and 1800mm deep this chamber is ideal for valve, actuator, pump, flow metre and cable assemblies including connections and penetrators.

|

|

|

|

|

|

200 bar chamber

This medium equipment chamber has a working pressure of 200bar and is ideal for pressure testing power supplies, cable assemblies, small electrical housings, underwater cameras and lights. One of the features of this chamber is its 6 multi-way penetration ports which allows easy access for monitoring equipment testing.

|

|

|

|

|

|

Viewport test Jig

A viewport jig for high pressure testing of acrylic viewports used in saturation diving complexes and submarines is available at the NHC.

The use of acrylic plastic viewports has been standard for many years, however the development of polarised light testing has shown that there are various misconceptions about them. Acrylic viewports which are used under pressure are subjected to an increased rate of yield, giving them a slight permanent deformation and inbuilt stress. It is generally agreed that acrylic viewports should be replaced after 10 years of service.

Referring to IMCA guidance D047, viewports should be certified before use:

“Viewports should be subjected to proof stress testing and relevant certification provided

before installation.”

“All viewports in a pressure system need to be rated to the design pressure of the system.”

“Viewports which are not marked or properly documented should not be used.”

All viewport tests are independently witnessed by a class society. Successfully tested viewports are marked with indelible ink - date of examination.

|

|

Facilities |

|

|

|