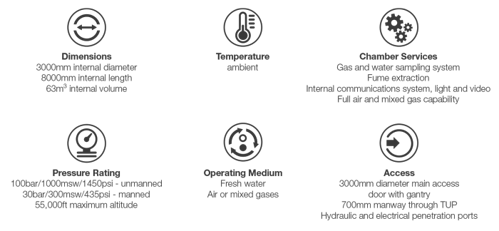

JFD maintains one of the largest hyperbaric test facilities in the UK and provides an impressive suite of services for research, development and testing.

Our facilities are amongst the largest in the world, capable of simulating depths up to 800bar and altitudes of 55,000ft.

We offer a complete capability, from design and manufacture. Through to operation, maintenance and training.

The variety of chambers enable us to pressure test a wide range of equipment of all shapes and sizes such as subsea control modules, umbilicals, valves, actuators, ROV and submersible vehicles, buoyancy control devices and underwater housings. Alongside the capacity to altitude test equipment and products across a range of markets.

Specification

|

|

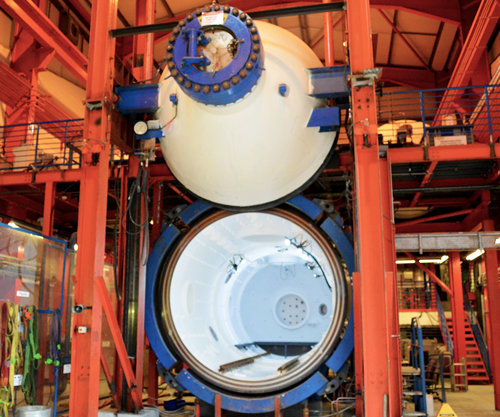

| Work Chamber |  |

| Work chamber showing access door |  |

| Work chamber showing access door Submarine testing within work chamber |  |

| Manned trials |  |

| Valve testing within work chamber |  |

The National Hyperbaric Centre’s deep equipment chamber is again similar to its other chambers but has a much higher pressure rating, down to an impressive 8000m and again is ideal for power supplies, cable assemblies, small electrical housings, underwater cameras and lights in a wet, dry or gas filled environment.

|

|

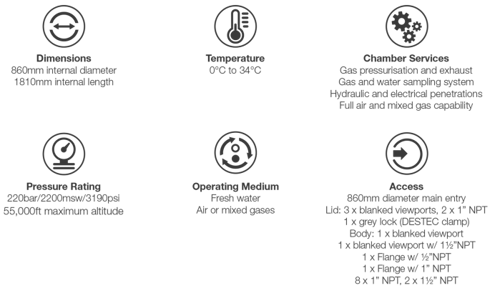

National Hyperbaric Centre also has several smaller chambers, including our 220bar chamber, capable of pressure testing to 2200m. With internal access of 860mm wide and 1800mm deep this chamber is ideal for valve, actuator, pump, flow metre and cable assemblies including connections and penetrators.

|

|

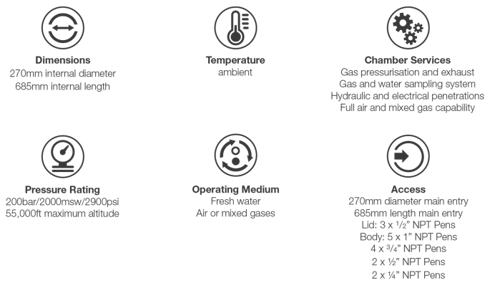

This medium equipment chamber has a working pressure of 200bar and is ideal for pressure testing power supplies, cable assemblies, small electrical housings, underwater cameras and lights. One of the features of this chamber is its 6 multi-way penetration ports which allows easy access for monitoring equipment testing.

|

|

A viewport jig for high pressure testing of acrylic viewports used in saturation diving complexes and submarines is available at the NHC.

The use of acrylic plastic viewports has been standard for many years, however the development of polarised light testing has shown that there are various misconceptions about them. Acrylic viewports which are used under pressure are subjected to an increased rate of yield, giving them a slight permanent deformation and inbuilt stress. It is generally agreed that acrylic viewports should be replaced after 10 years of service.

Referring to IMCA guidance D047, viewports should be certified before use:

- “Viewports should be subjected to proof stress testing and relevant certification provided

before installation.” - “All viewports in a pressure system need to be rated to the design pressure of the system.”

- “Viewports which are not marked or properly documented should not be used.”

All viewport tests are independently witnessed by a class society. Successfully tested viewports are marked with indelible ink - date of examination.

Facilities:

-

Hydro testing of viewports

-

Accepts flat or conical acrylic viewports used for diving chambers and submarines

-

Designed with an interchangeable core to allow various sizes and shapes of viewport testing

-

150bar/1500msw

Our world-class facilities and capabilities are ready to support your next project.

Read James Fisher and Sons plc's latest Annual Report

Read James Fisher and Sons plc's latest Annual Report